|

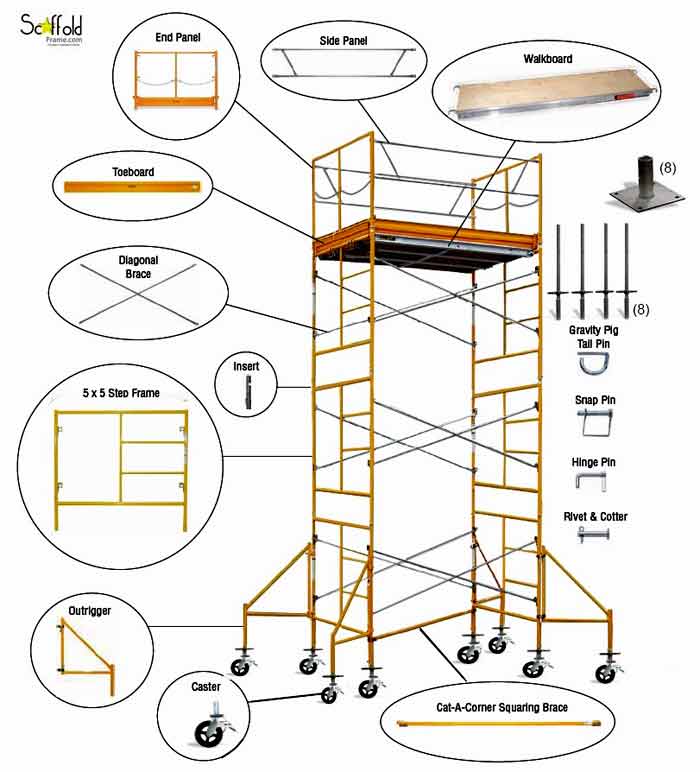

Scaffolding Tower Resource Link Scaffold Frame Scaffolding Towers Scaffolding towers (also known as scaffold towers, tower scaffolding, rolling scaffold and sometimes rolling towers. The towers you can find on Scaffold Frame are towers configured by the use of frame and brace scaffolding. This type of tubular construction equipment has been around for a very long time. It is strong, dependable, and is relatively low in cost. Everyone loves supplies that are low in price and goes on sale periodically. Scaffold tower can be erected in all shapes and sizes. The standard dimensions are 5 foot and 7 foot long. Reaching 5 foot high all the way up to 30 feet tall. This would be in reference to stand alone scaffold towers. Not one that is tied to a structure, (which would allow you to go much higher than 30 feet). Also they can be mobile or stationary. Building Your Own Scaffold TowerSome people would like their own customized scaffold towers. They can decide on which material to use and also the desired dimensions. They can also choose if they want it mobile or stationary. In addition, there is a lot of information regarding building your own scaffold towers on the Internet. And also, there are lots of sites that sell scaffolding spare parts. (www.scaffoldframe.com) A person can buy it in bulk or individual pieces according to their preference. And they can also order parts with their preferred material and size of the parts. Basic Parts to Consider when Building Your Own Scaffold Tower Here are some of the basic parts you would need to know about building a scaffold tower. Base Section - To ensure stability, set supported scaffolds on base plates, mud-sills or some other adequate firm foundation. Supported scaffold poles, frames and uprights must be plumb and braced to prevent any displacement caused by swaying. The Scaffold cross braces should never be used as a means of access. A specific access, such as a mounted ladder, must be used. Bracing Connect panels and frames with diagonal, horizontal, or cross braces along or as a combination, in order to laterally secure the vertical members. Because the frames are stacked, the cross braces have to keep the scaffold plumb, level, and square. All brace connections must be secured to prevent dislodging. Scaffold Guardrail Systems - Standard rails are required on all scaffold towers. They should be installed along all open sides and at both ends of platforms, except when used as a walkway, the platform is the main working area of the scaffold. Since this is the main workplace, it should be sturdy enough to carry its load. Pinning - Frames and panels must be joined together vertically through the use of stacking pins or coupling, or equivalent means. Frames and panels should also be locked together to prevent uplift. These are only a few basic physical structures of scaffold towers. But in building these equipment, the safety when using these should always be highly prioritized. Since it is an elevated platform, the stability decreases as the height increases. In addition, the scaffold and its components must support, without failure, its own weight and at least four times its maximum intended load. Stability and durability are the key components for the scaffold towers to be safe. Scaffolding A common type of standard scaffolding used in the US is tube and clamp scaffolding, which is assembled by fixing together all the different components. The main components are scaffolding tubes, scaffold clamps, and base plates. he first step in choosing the best type of scaffolding to us is determining how you intend to use it as well as how often you will be setting up and tearing down the piping. This will have an impact on what components you will need as well as how many of each component will be necessary to complete your tasks. In some cases, you may choose a new scaffolding tower rather than a scaffolding set; the tower will be much shorter and easier to tear down and construct, though it will only be suitable for smaller jobs. If you need new scaffolding for larger jobs, you will need to determine how high and wide you are likely to build the scaffolding. This will determine how many of each component you will need. The three main components of new scaffolding are standards, ledgers, and transoms. You will need many of each component for larger structures. Standards are vertical pipes that are connected with clamps or couplers to give the structure its height; ledgers are horizontal braces that steady the structure and give it width. Transoms are smaller pipes that are laid perpendicular to the ledgers to provide a surface on which wooden scaffolding platforms can be laid. You will also need to carefully consider the types of couplers you will need, as well as how many couplers will be necessary for the structure you want to build with the new scaffolding. Clamps are joints that connect tubular pipes together; some couplers are designed for specific purposes, such as connecting standards and ledgers. Others, such as swivel couplers, can be used for a variety of purposes; they can be positioned to allow various angles and crosses among the types of piping. One must also consider all the necessary components and hardware needed in order to have the safest most accessible construction work platform. Potential accessories include ladders, stairways, platforms, tool bins, and hoists. Ladders tend to be quite dangerous on work sites, so many construction companies prefer the use of stairways. The drawback to stairways, however, is the amount of space they are likely to take up in the overall structure. Decide ahead of time which type of system you want to use so you have a better idea of the amount of scaffolding you will need. Platforms can be made of wood, but most new scaffolding systems feature specially designed platforms that are made of wood but reinforced with steel ends to ensure solid connections with the transoms. Consider such platforms for added stability and safety. Scaffolding Tools The main tools involved in scaffolding are basic construction tools, ladders, power machines and also very specific safety equipment such as safety glasses, ear protectors, fall arrest equipment and so on. Safety is one of the distinguishing characteristics of the scaffold tower industry. Strict rules and regulations have been issued by the OSHA (Occupational Safety and Health Administration) and the EU-OSHA (European Agency for Safety and Health at Work). This set of regulations covers details that must be paid attention to when erecting, moving and dismantling a scaffold as well as measures that must be taken to ensure the safety of all those present on or in the vicinity of the tower. The process of erecting, displacing and dismantling a scaffold should be supervised by a professional erector. Independent Scaffolds There are a great number of different scaffolds and scaffolding towers: they can be generally classified as independent scaffolding. Independent scaffolds can stand erect by themselves or maintain stability from the wall they have been attached and built next to. Basically this is referring to a stand alone structure with platform. Mobile Scaffold Towers Rolling interior and exterior scaffolding are referred to as mobile scaffold towers, and they are a type of scaffolding tower that have scaffolding casters attached to the end of all the scaffold legs on which they stand: these can be swiveled and moved around to be employed as work support in different locations without less need of dismantling and then reconstructing them. Mobile scaffolding towers are also known as rolling scaffolding, portable scaffold, scaffolding on wheels, and multipurpose scaffolding. Steel and Aluminum Scaffolding Towers Aluminum and steel are the most commonly used materials around the world for scaffolding and tower scaffolds. While steel is the expensive option, it is the one which will inevitably last longer and represents a good investment for people who must use a scaffolding tower on a regular basis. Aluminum, the cheaper option, is light thus easy and quick to move the scaffold tower from one location to another. Scaffold Frame keeps only high grade steel scaffolding in inventory, but aluminum scaffold is available on request. Other Materials In certain industries such as oil refinery, aviation, gas and chemical manufacture it is necessary to use glass fiber structures as these will not spark or corrode in situations where gasoline, solvents, electricity and so forth are present. In Asia, bamboo is used as a construction material. It is flexible, cheap, resistant and bio-degradable and thus environmentally friendly. Scaffolding Regulations and Maintenance Maintaining a scaffold or tower scaffolding is of crucial importance, especially if the structure is intended to last for a long time. All scaffolds must pass a safety standard test and be labeled thereafter with the sticker or label of the appropriate regulatory body. All scaffolding products available at scaffoldframe.com meets OSHA and ANSI standards, and have a 5 year warranty*. Click here to learn more about Scaffolding Regulations. Diagram of a Rolling Scaffold Tower |